Leachate treatment technology package

Leachate & special wastewater separation low-consumption ultrafiltration equipment

Landfill leachate is highly concentrated organic wastewater with organics, heavy metals and salts. Traditional UF has short life, high energy and hard maintenance. Existing processes meet capacity and standards but ignore low energy; they cannot meet low‑carbon needs.

Common processes and pain points

Pain point 1: Short lifespan

External tubular ultrafiltration has a short lifespan and is easily clogged by oil, fiber, particles and other dirt; service life generally about 3 to 5 years.

Pain point 2: High energy consumption

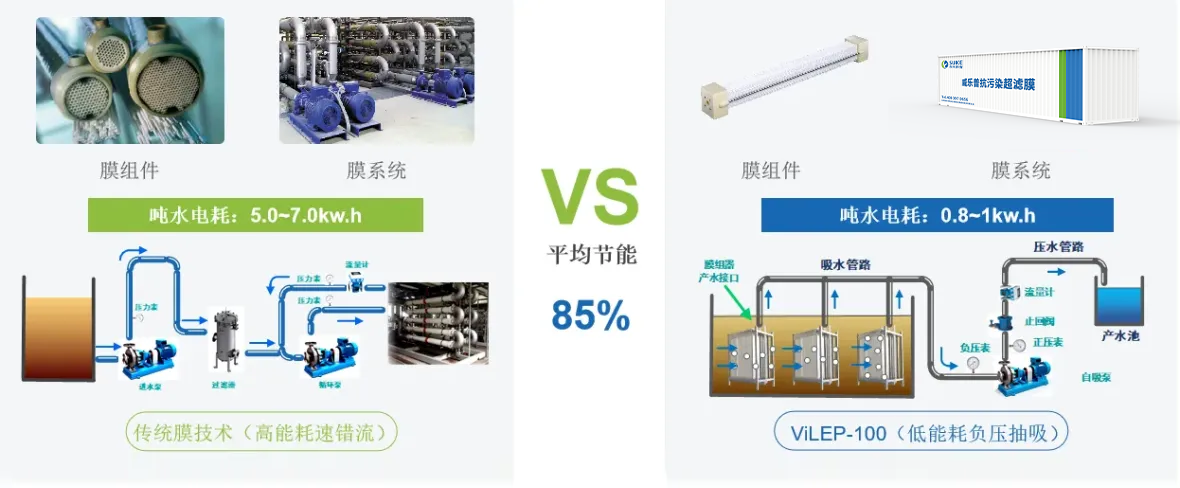

Cross‑flow filtration consumes high energy; treating high‑TDS streams is costly due to elevated electricity demand.

Pain point 3: Difficulty in cleaning and maintenance

Traditional units are not resistant to oil or drug contamination; fiber hair is difficult to clean and disassembly is complicated.

Adaptive product series

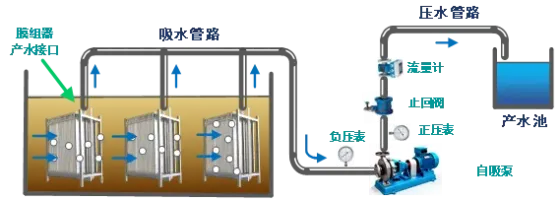

Aerated membrane bioreactor

Traditional aerated MBR. Continuous/pulsed aeration. Municipal and industrial.

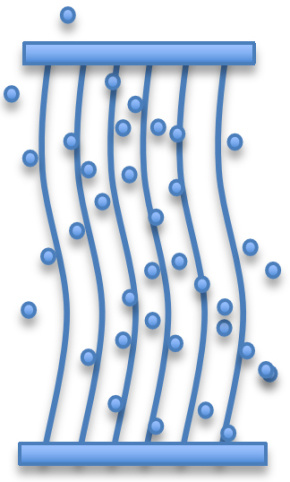

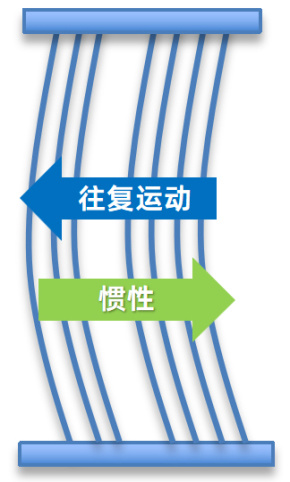

ViLEP technology

Hydrophilic PTFE vs traditional fluororesin: longer life; vibration scrub vs aeration scrub.

Energy consumption reduced by 85%+

Illustrative comparison of different process routes and typical engineering applications. Replace the following images with the exact assets from the design.

Overview

For leachate and special wastewater, this package offers ViLEP low‑energy anti‑pollution vibrating membrane. For new builds and retrofits; strong oil/anti‑fouling, easier maintenance, ~1 kWh/ton, doubled life, stable low‑carbon operation.

Technological advantages

Oil resistant and

pollution resistant

Sumitomo Electric POREFLON hydrophilic fluororesin resists organic, scaling and cellulose fouling in high‑load leachate.

1 ton of water

1 kWh of electricity

Compared with traditional tubular membranes, ViLEP uses only about 0.8–1.0 kWh per ton of water.

Double lifespan

Service life 5–10 years vs 3–5 years for traditional.

Easier

maintenance

Longer cleaning cycle (~90 days), halving O&M effort.

We provide equipment products

- Oil‑resistant, anti‑pollution, stable operation

- Low energy consumption; ~1 kWh per ton of water

- Extended service life; reduced replacement frequency

- Modular, easy installation and maintenance

- Wide adaptability to seasonal and shock loads

Application highlights

Long lifespan

Completely remove pollution; strong oil and chemical resistance

Low energy consumption

Simple negative pressure suction plus vibration

Easy to clean & maintain

Strong oil and chemical resistance; easy maintenance